Mechanical Services

Technical Design & Manufacturing

Technical Design

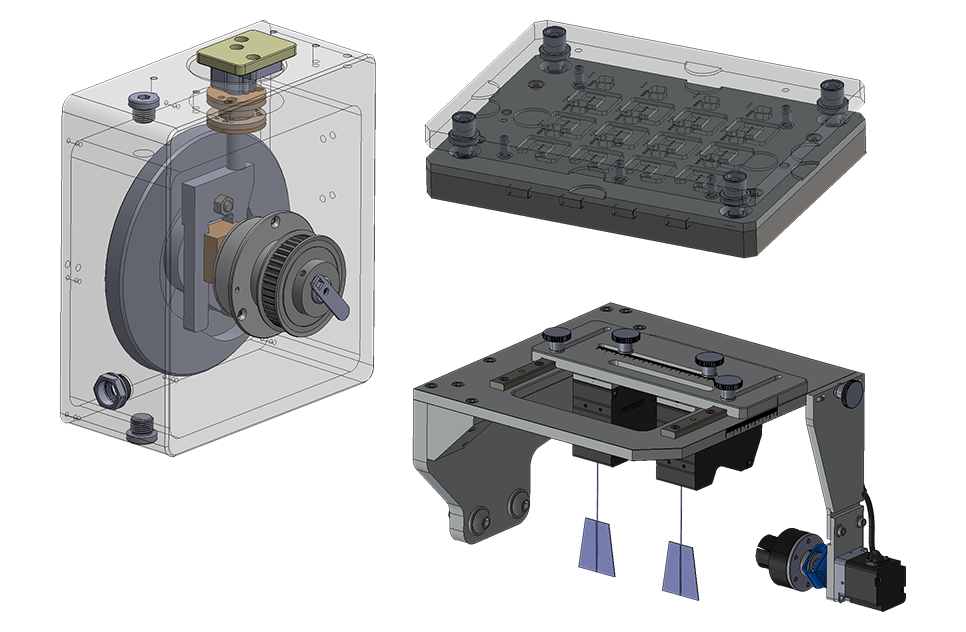

Protyping and production designs for any application

Precision Machining

CNC maching equipment for milling, turning & grinding

Fabrication

Bespoke welding fabrication work, including testing

Technical Design

APS has assisted its global customers through the ongoing development of inventive production methods, affording significant increases in 'right first time production'.

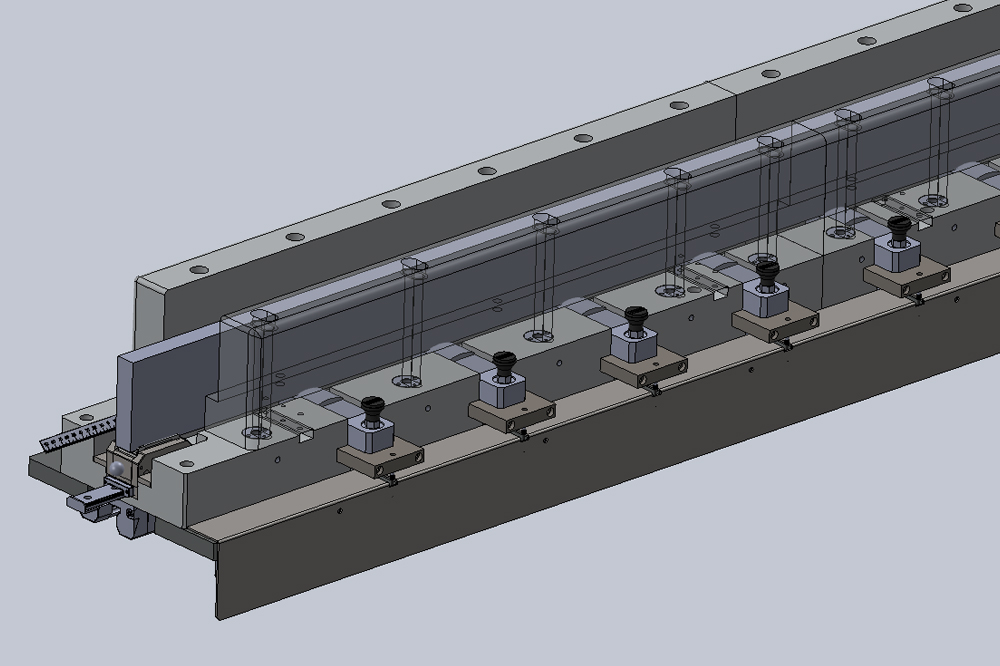

Computer Aided Design (CAD)

Our experienced design engineers from wide-ranging industrial backgrounds develop an initial proof of concept for achieving higher levels of efficiency in your manufacturing.

Each concept is then realised and simulated using SolidWorks or Solid Edge. Protypes are created, as required, to enable thorough reviews of the resulting designs and their corresponding FMEA. Through these steps, your business can deploy new production methods with confidence.

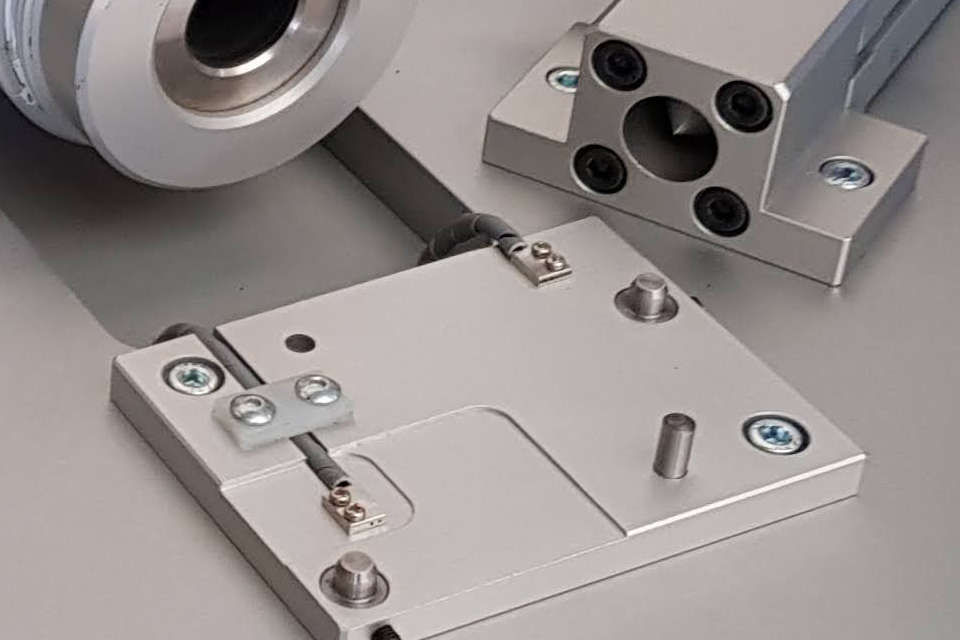

Manufacturing

Extensive in-house machining, fabrication, and finishing capabilities allow us to offer a fast turnaround manufacturing service for time-sensitive projects. Where we do not have the capability to perform a certain process in-house we use our network of reliable, audited, and approved sub-contractors. Some of our capabilities are detailed below.

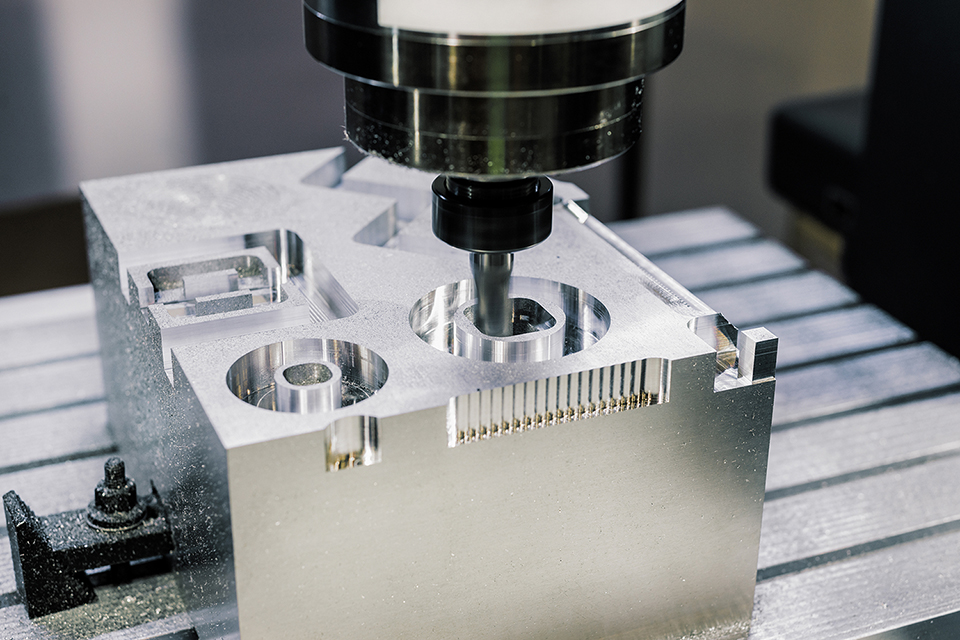

Milling

Up to 5-axis precision CNC milling across two machining centres

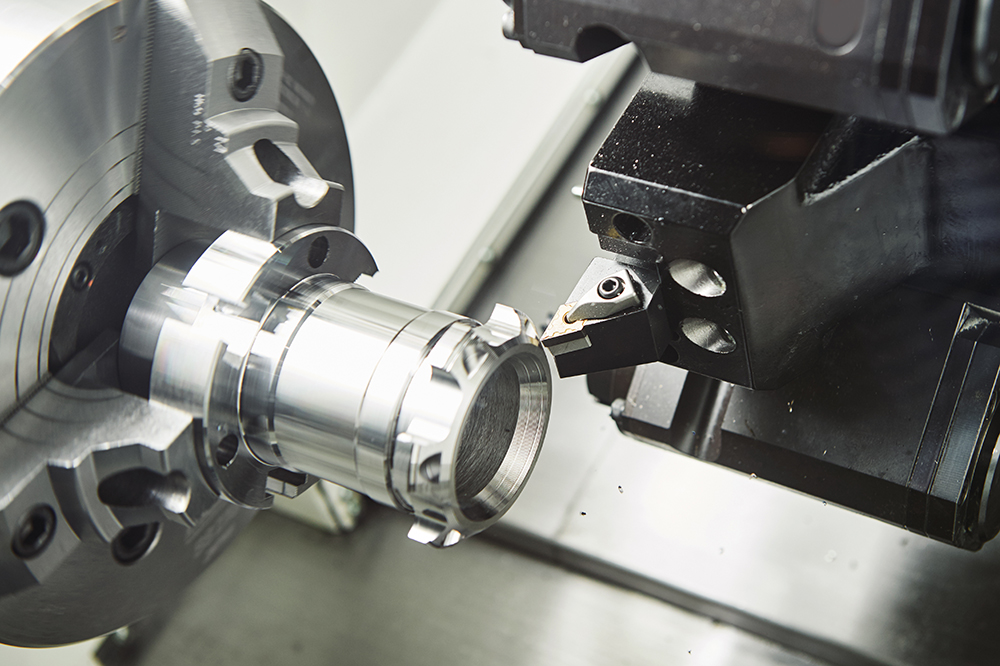

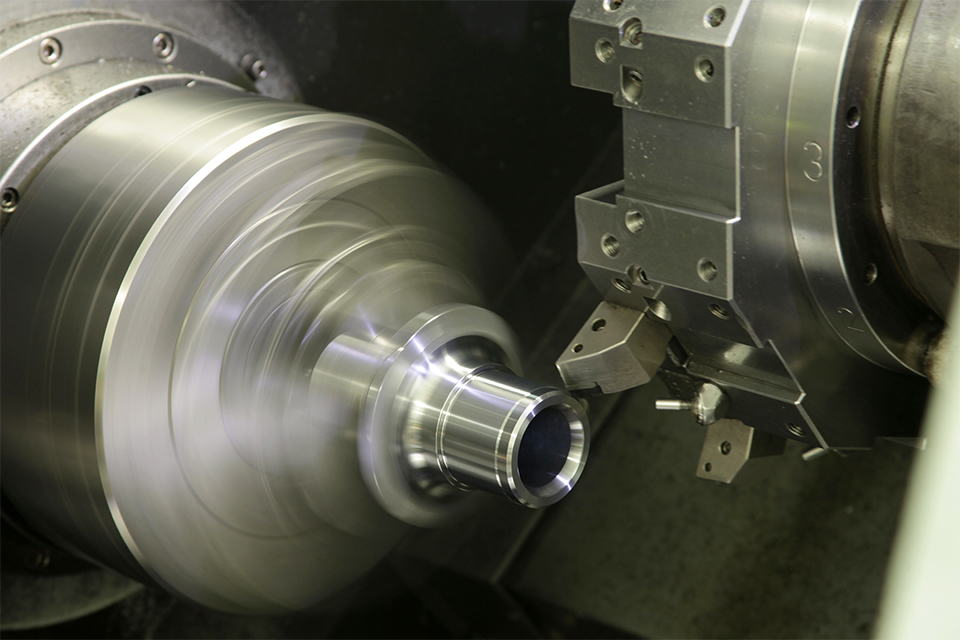

Turning

Three CNC lathes for turning parts up to 2m in length, including auto-feed production

Grinding

Centreless, cylindrical, and surface grinding for tight tolerances

Laser Marking

The latest 3D laser marking technology for the clearest quality part marking

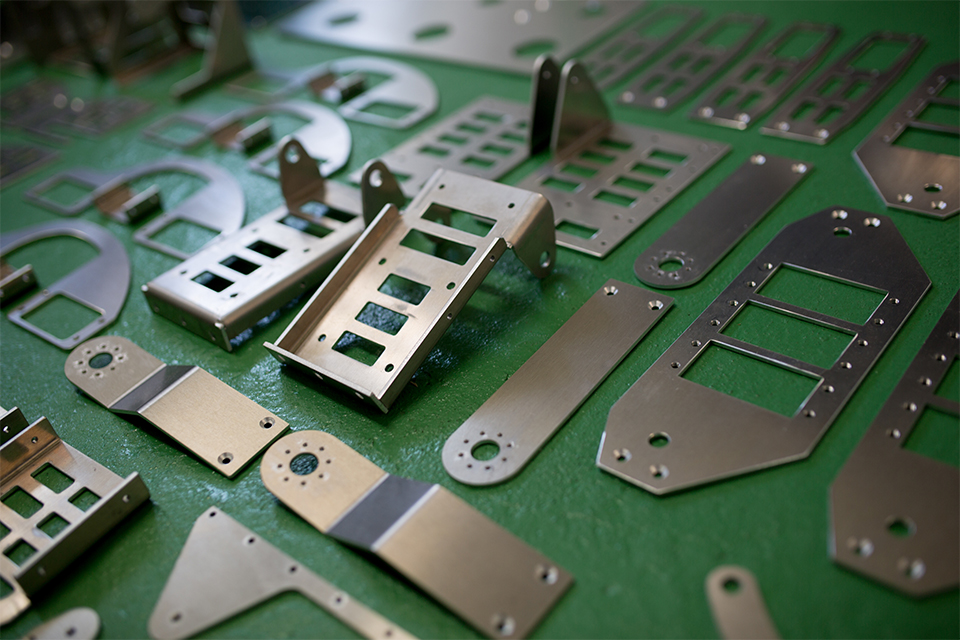

Sheet Metal

Close tolerance sheet metal components for a variety of applications

Vapor Blasting

Vapour blasting results in a superior surface finish and uniform aesthetic

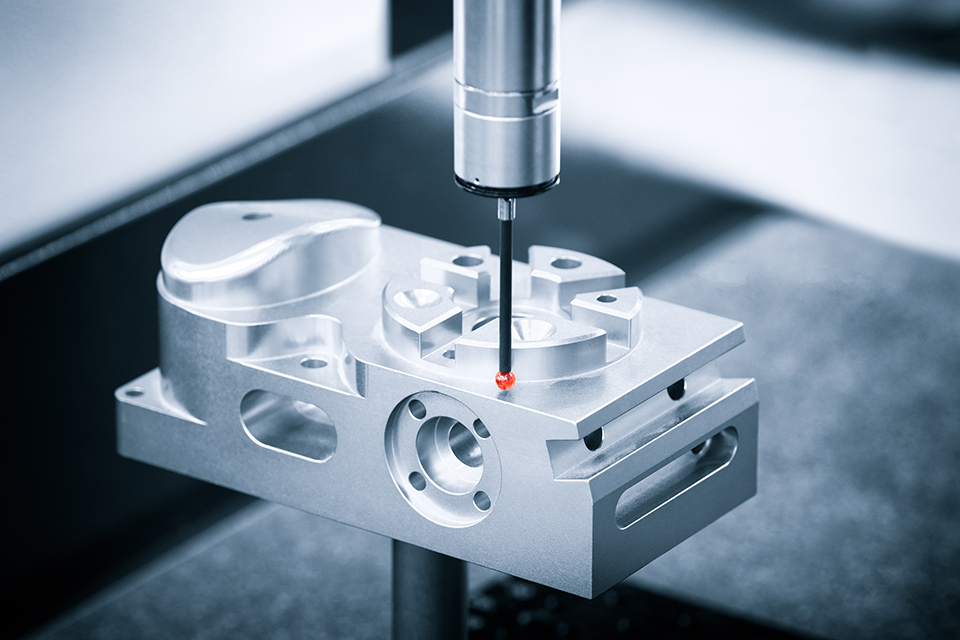

Quality Assurance

With a growing number of customers requesting various documents for their internal quality records, we can supply all levels of material certification according to EN 10204:2004 as required, in addition to our internal process traceability.

If necessary, we can also provide first-article inspection reports for all components and assemblies using our calibrated CMM and laser profiling equipment.